Reisopack

2100

High performance automatic strapping machine. Very fast. Maximum reliability.

- Designed and manufactured using highest quality components.

- Aluminium head set and treated tension roller ensures long life of the machine.

- Tension electronically adjustable through a magnetic clutch to get the strongest tension without any physical effort.

- Electronic control of the tension, heating, cutting and length of the strap.

- Adjustment of the cooling after sealing to get better sealing quality, especially for hard packages (wood, iron, etc).

- Available in a range of different dimensions of arch.

- Double magazine for big arches.

- Movement of the all machine to look for the pallet.

- Machine prepared to be putted in an automatic line.

The lance puts the strap in the gap of the pallet.

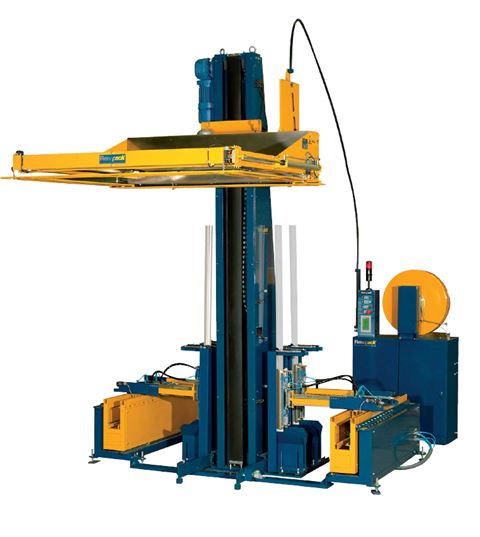

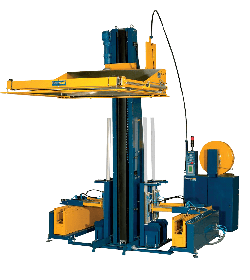

2210

Automatic machine with press for the vertical strapping of cardboard on pallets.

- Our own in-house manufacture and technology using top quality European components.

- Aluminium head, tempered tension rollers for longer machine lifeAdjustable tension through clip system.

- Adjustable press for packet compression up to 1,600 Kg.

- Motorized strap feed and guidance.

- Electronic control of the entire strap tensioning, sealing, cutting and ejection process.

- Incorporated selector for polypropylene and polyester strapping.

- Equipped with seal cooling timer to improve seal quality.

- Prepared for integration into fully automatic lines

- Safety standards. CE mark.

- Double-chain press feed.

- Transportation connection hooks.

- Roller conveyor incorporated into the lower part of the machine.

- Telescopic bayonet.

- Turncross.

- Closed arch and bayonet.

- Press up to 3,000 Kg.

2903

Useful system, simple and easy to program. Suitable for use in fully automated lines.

- Own manufacturing and technology using highest quality components.

- Compression system in the arch compacts load and guides the strap to the correct position.

- Mechanical tension adjustable through a holding strap system to get the highest tension.

- Aluminium head Reisopack 1900 long lasting.

- Approximate production higher than 60 pallet per hour.

- Security system under the arch with reverse engine.

- Visual signaling errors.

- Touchscreen control 5'6 inch TFT LCD.

- Able to store up to 10 different strapping programs.

- Can be integrated into a fully automated line.

- Electronic tension.

- Strap empty alarm.

- CRC technology to perfectly reposition of the corners.

- Side compactor system.

Control panel with touch screen with selection of the operating language.

2901

Horizontal strapping machine with automatic corner applicator, easy and user-friendly set up. Ready to be built into a complete automatic line.

- Own technology and manufacture using European components of highest quality.

- Easy memorization of the different heights of strapping by pressing a button when the machine is in the desired position. Possibility of saving 10 different heights in 10 different programs.

- Automatic corner applicator.

- Pressing system in the arch to compact the loads and guide the strap.

- Corner application air system by means of 4 telescopic L-shaped arms, adjustable to the size of the pallet.

- Adjustable tension by means of high-tension clamp system.

- Reisopack model 1900 aluminum strapping head ensures long life of the machine.

- Approximate production of 50 pallets/hour with 4 corner boards and 3 straps.

- Security system with inversion of the motor direction.

- Failure warning lights.

Model 2901

The strapping machine 2901 requires that in the entrance position, the shortest side of the pallet should be parallel to the machine.

Varianta 2904

The strapping machine 2904 requires that in the entry position, the longest side of the pallet should be parallel to the machine.

Varianta 2903

The strapping machine 2903 is prepared assemble the corner applicator and enables the entrance of the pallets from both sides.

The corners application is fast and precise. It can be set within many different programs which enable to adapt the strapping to the product.

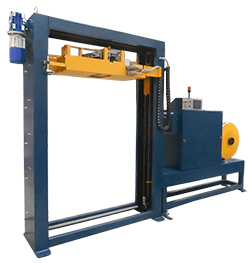

2200

Automatic machine for the vertical strapping of pallets irrespective of their size.

- Our own in-house manufacture and technology using top quality European components

- Aluminium head, tempered tension rollers for longer machine life

- High tension levels achieved through adjustable clip system

- Electronic control of the entire strap tensioning, sealing, cutting and feed process

- Incorporated selector for polypropylene and polyester strapping

- Equipped with seal cooling timer to improve seal quality

- Prepared for integration into fully automatic lines

- Safety standards. CE marking

- Available in a multitude of different sized arches, from 1,000 mm to 3,000 mm, in both width and height

- Telescopic bayonet for strapping pallets by passing the strap through the pallet woodwork

Possibility to integrate in automatic lines

1920

AT

AT

Automatic standard strapping machine with excellent performance with 12 mm strap.

- Compact and reliable strapping head with great durability.

- Auto strap re-feeding.

- Automatic feeding system.

- Short feed detector.

- Electronic tension control

- Auto strap ejector.

- Quick coil change system.

- Sensor controlled welding.

- Strap end ejector.

- Rotating wheels.

- Autostart by photocell.

Coil located at waist height with quick change system.