Movitec

S8

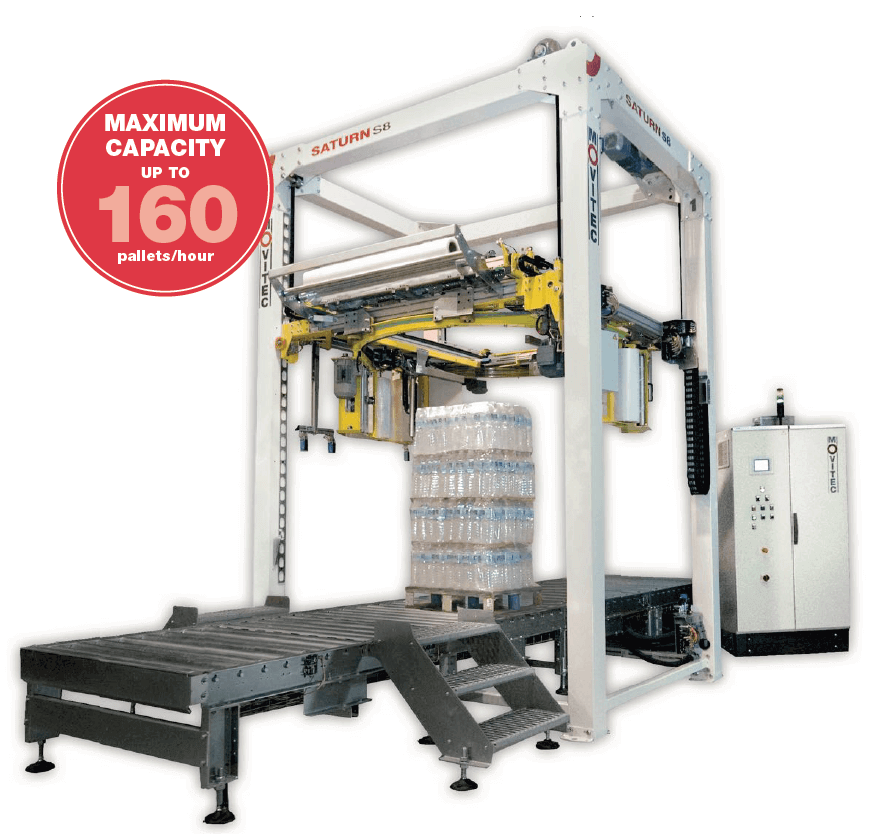

SATURN

SATURN

SATURN S8 is a totally automatic pallet stretch ring wrapping machine for wrapping palletized loads with stretch film. The SATURN S8 machine has been designed to cover the markets with maximum productions.

It is equipped with double unwinder, which allows you to apply two turns of film in a single loop, granting a productive capacity of up to 160 pallets / hour, becoming the fastest machine, without reducing the efficiency and reliability that characterizes our machines.

- MAXIMUM CAPACITY: up to 160 pallets/hour.

- Maximum quality, high performance and minimum maintenance.

- Double unwinding head.

- The load remains static: the film reels rotate around the load.

- Guaranteed savings of stretch film: 300% film pre-stretching.

- 1m of film becomes 4 m.

- Finishing without tails of film thanks to our efficient cut and welding device.

- Electronic and self-adjusting tension control depending on the profile of the load.

- Possibility of applying efficient dustproof and rainproff wrappings.

- Possibility of wrapping at ground level.

- Capable of applying bands (strips) at any height of the load.

S6

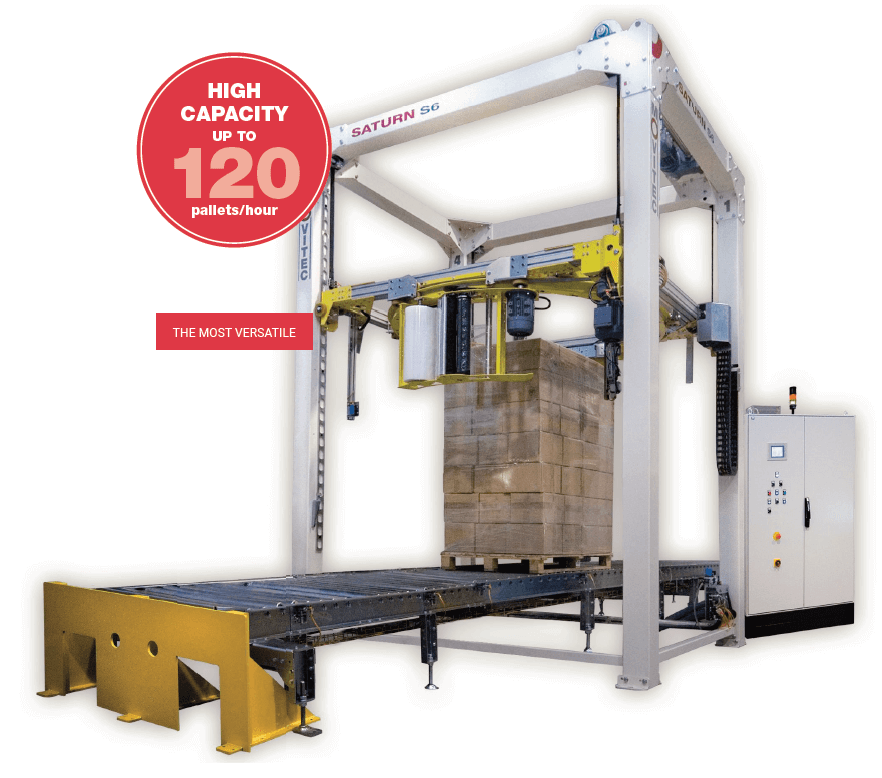

SATURN

SATURN

SATURN S6 is a totally automatic pallet stretch ring wrapping machine for wrapping palletized loads with stretch film. The film reel is mounted on the ring, which rotates concentrically to the load going up and down depending on the wrapping cycle, so the load remains static.

Designed to cover the markets with demanding productions, up to 100 pallets / hour, it is our most sold and versatile machine.

The ring technology of our SATURN S6 has a more balanced system, with less wear and less maintenance than the other technologies available in wrapping.

- HIGH CAPACITY: up to 120 pallets/hour.

- Maximum quality, high performance and minimum maintenance.

- It is the most versatile: it can evolve to a Saturn S8 model to get higher capacities.

- The load remains static: the film reels rotate around the load.

- Guaranteed savings of stretch film: 300% film pre-stretching.

- 1 m of film becomes 4 m.

- Finishing without tails of film thanks to our efficient cut and welding device.

- Electronic and self-adjusting tension control depending on the profile of the load.

- Possibility of applying efficient dustproof and rainproff wrappings.

- Possibility of wrapping at ground level.

- Capable of applying bands (strips) at any height of the load.

S4

Saturn

Saturn

The SATURN S4 wrapper has been designed to cover the markets with medium productions, up to 60 pallets / hour, being the best alternative to the arm wrapping machine.

The SATURN S4 wrappers equip the best technology available on the market, as well as the rest of our models with higher productive capacity, with electronic tension control and self-adjusting according to the load profile, which prevents film breakage or deformation of the load, ensuring maximum stability with the minimum film consumption.

- MAXIMUM CAPACITY: up to 70 pallets/hour.

- Maximum quality, high performance and minimum maintenance.

- It is the best alternative to the rotating arm wrapping machine: more balanced, with less mechanical wear and maintenance.

- Guaranteed savings of stretch film: 300% film pre-stretching. 1m of film becomes 4m.

- Finishing without tails of film thanks to our efficient cut and welding device.

- Electronic and self-adjusting tension control depending on the profile of the load.

- Possibility of applying efficient dustproof and rainproff wrappings.

- Possibility of wrapping at ground level.

- Capable of applying bands (strips) at any height of the load.

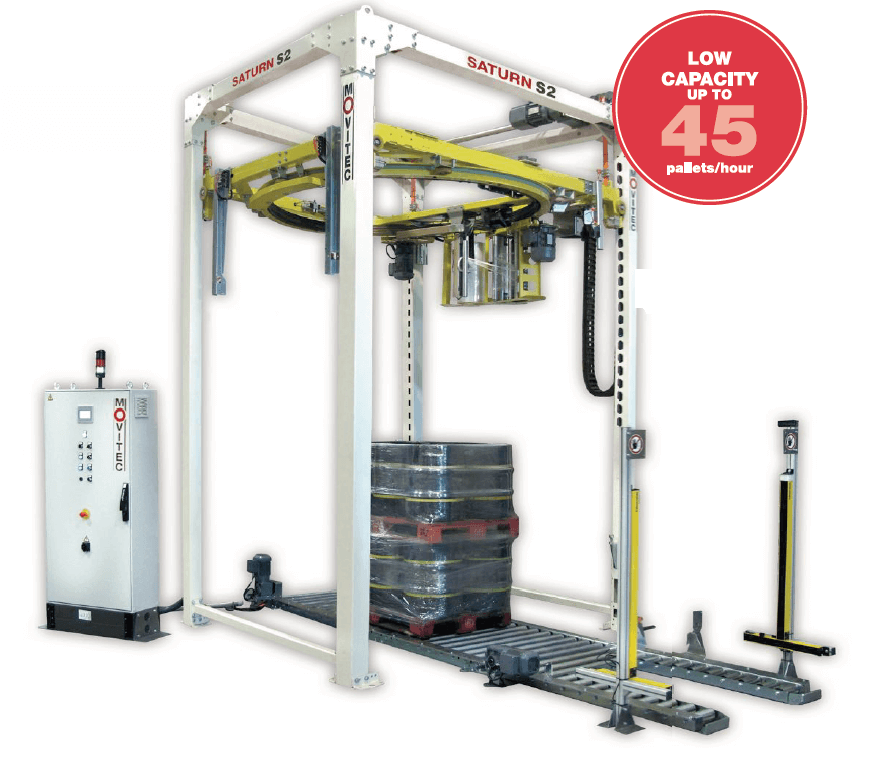

S2

Saturn

Saturn

The SATURN S2 wrapper has been designed to cover markets with low production, up to 45 pallets / hour, which until now were equipped with turntable wrappers or rotary arm.

- LOW CAPACITY: up to 45 pallets/hour.

- Maximum quality, high performance and minimum maintenance.

- It is the best alternative to the turntable wrapping machine: more balanced, with less mechanical wear and maintenance.

- The load remains static: the film reels rotate around the load.

- Guaranteed savings of stretch film: 300% film pre-stretching. 1 m of film becomes 4 m.

- Voltage: 3 x 400 Vac / 50Hz +N +PE

- Power supply: 3 kW

- Compressed air: 6 bar

- Air consumption: 8 l/cicle

- Air consumption with top film: 64 l/cicle

- Finishing without tails of film thanks to our efficient cut and welding device.

- Electronic and self-adjusting tension control depending on the profile of the load.

- Possibility of applying efficient dustproof and rainproff wrappings.

- Possibility of wrapping at ground level.

- Capable of applying bands (strips) at any height of the load.